The largest application for the Ansac HK Series Indirect Fired Rotary Kiln is in the field of carbon regeneration for the gold mining sector in conjunction with carbon-in-leach and carbon-in-pulp extraction methods.

Activated Carbon is used in numerous industries as an adsorber of contaminants from waste water, air and slurries; many users simply dispose of the spent activated carbon but the more savvy or cost sensitive businesses will thermally treat the spent activated carbon in order to regenerate or reactivate it multiple times.

The gold industry utilises activated carbon to extract gold from a cyanide slurry (carbon-in-leach or carbon-in-pulp) solution into a highly concentrated electrowinning feed. Unfortunately, gold is not the only chemical species adsorbed in the slurry tanks. Other contaminants; particularly organic volatile materials are also captured. These contaminants, or foulants, will decrease the number of sites or locations on the activated carbon particles for the gold to be adsorbed.

Often, after only one cycle through the slurry tanks, the activated carbon will drop to 30-50% of the activity levels of fresh new activated carbon. This effect is cumulative and after several cycles, the ability of the activated carbon to capture gold will be almost nil.

Activated carbon must be reactivated or regenerated back to as close to as new condition as possible for the adsorbtion process to remain efficient.

In practical terms, three key factors are necessary to reactivate or regenerate carbon:

− Temperature

− High Steam Partial Pressure

− Residence Time

Carbon at 650°C exposed to air will combust. Regeneration, however, requires a special atmosphere of steam and inerts in order to prevent combustion and remove volatiles and foulants. Activated carbon, due to its incredibly porous nature, retains almost its entire weight in water. Even when carbon feels dry, it can still contain well over 35% moisture.

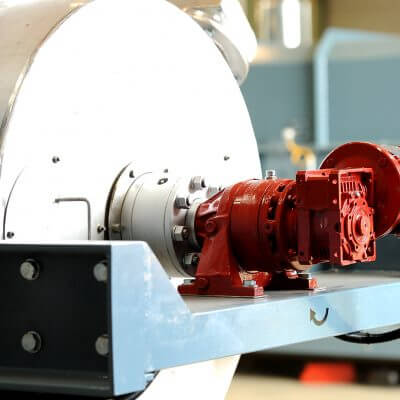

Using this information Ansac has developed a kiln around the principle of co-current self-generating steam. The unique HK Series design utilises a co-current gas flow; the hottest gas now contacts with the coolest carbon as opposed to vice versa, eliminating the risk of the carbon igniting or creating hotspots.

The Ansac HK Series Kiln maximises the performance of the carbon circuit, offering unparalleled carbon regeneration whilst keeping the operating costs to a minimum.

20 years of experience in carbon regeneration has made Ansac the industry standard in carbon regeneration and has led to improvements that have made Ansac’s unit the most capital and operating cost effective options in the market.

For more information on Ansac’s Carbon Regeneration Kiln please contact us via info@ansac.com.au